5 Things to Consider Going from a Dairy to Beef Operation

Dairy milkers wanted. Sound familiar? A quick search shows 230 open jobs right now just in the state of Wisconsin. An increased need for labor, equipment and implementing modern practices has squeezed many small and medium sized dairies out for the large scale operations to make it work. Now, people are looking to the beef […]

ART’S WAY ANNOUNCES 40.7% INCREASE IN CONSOLIDATED REVENUES, $986,000 INCREASE IN CONSOLIDATED OPERATING INCOME FOR FIRST FISCAL QUARTER OF 2023

FOR IMMEDIATE RELEASE April 6, 2023 ART’S WAY REPORTS Q1 IMPROVEMENT FOR FISCAL 2023 YEAR ON YEAR; 40.7% REVENUE INCREASE, $986,000 INCREASE IN OPERATING INCOME ARMSTRONG, IOWA, April 6, 2023 – Art’s Way Manufacturing Co., Inc. (Nasdaq: ARTW) (the “Company”), a diversified, international manufacturer and distributor of equipment serving agricultural, research and […]

FRESH LOOK, LEADERSHIP AND DEALER SUPPORT MODERNIZES ART’S WAY MANUFACTURING

In 1956, a Northwest Iowa farmer built his own PTO-powered grinder mixer. Arthur Luscombe’s invention marked the beginning of Art’s Way Manufacturing. Now, in 2023 the publicly traded company (NASDAQ: ARTW) hosts more than 140 employees across three locations — with a product line as reliable as Art’s first-ever grinder mixer. Art’s way of doing […]

CHANGING COLORS: LOCAL SUPPORT, FAMILIARITY DRIVES MANURE SPREADER SWITCH

Colorado grower, Travis Herget, shares color conversion story Farming the front range of Colorado isn’t for the faint of heart. Navigating mountain terrain, high elevation and often-difficult, fluctuating temperatures make the right equipment choices especially critical. Growing corn, alfalfa and triticale near Platteville – a small town 40 miles north of Denver — Travis Hergert […]

Sugar Beet Harvester Adjustments

Harvester Adjustments

Top 4 Items to Maintain on Your Grinder Mixer

Grinders are a unique piece of farm machinery. They are one of the few things you mostly likely use year-round every day. Maintain your grinder mixer to minimizing downtime. Recently, we had visitors from our dealer, Helmuth Repair, at our factory. They provided the top 4 items to maintain on your grinder mixer including one […]

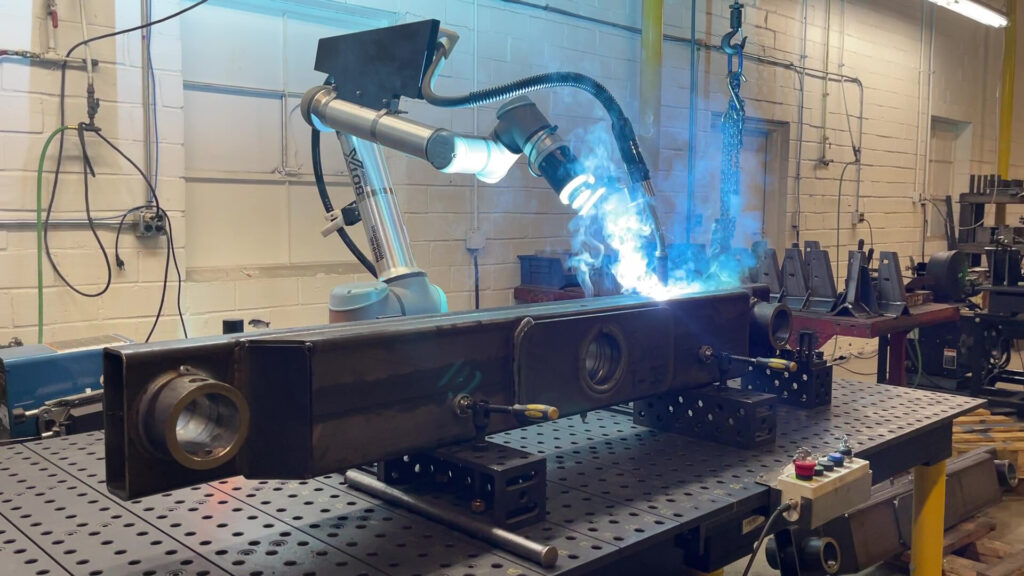

ART’S WAY AWARDED $500,000 THROUGH IEDA’S MANUFACTURING 4.0 GRANT

April 12th, 2022 Armstrong, IA. Art’s Way Manufacturing was awarded $500,000 through the Manufacturing 4.0 grant managed by the Iowa Economic Development Authority. The program was created following the pandemic in order to incorporate more technology into manufacturing. The strategic plan is to position Iowa companies for prosperity as we enter the 4th Industrial Revolution. […]

ART’S WAY MANUFACTURING ANNOUNCES UP TO $3 MILLION IN INVESTMENT FROM ALUMNI CAPITAL LP.

FOR IMMEDIATE RELEASE Armstrong, IA, April 4, 2022 – Art’s Way Manufacturing Co., Inc. (Nasdaq: ARTW), a diversified manufacturer taking pride in their livestock and sugar beet equipment, specialized tools, agricultural buildings and modular laboratories announced today that Alumni Capital LP has made a minority investment in the Company to support Art’s Way’s strategic direction […]

ART’S WAY TO ENHANCE DEALER NETWORK WITH MICHAEL LOUX, DIRECTOR OF SALES

Art’s Way Manufacturing strengthens its leadership team with the appointment of Michael Loux as Director of Sales effective March 21st, 2022. Michael grew up in Sac City, Iowa. He graduated with a bachelor’s degree in applied mathematics and a Professional Science Masters in industrial mathematics, both from the University of Northern Iowa. He later earned […]

New Art’s Way 2100 series forage box unload like a fire hose.

The affordable 2100 Series forage box offers a high-capacity option with a 100% in-cab hydraulic drive system that allows operators to take full control of the box from the cab. ARMSTRONG, Iowa, May 13 2021 — Art’s Way Manufacturing is staking its claim as the best box in the field with the introduction of the […]